EEO Statement

DEUTZ is an equal opportunity employer and considers all applicants for employment based on merit, competence, performance, and business needs. We do not discriminate on the bases of any status protected under federal, state, or local law. Applicants will be considered regardless of their race, color, sex, gender identity or expression, age, religion, creed, national origin, citizenship status, sexual orientation, genetic information, physical or mental disability, military status or any other characteristic protected under federal, state, or local law. In addition to complying with all applicable laws, DEUTZ also has a strong corporate commitment to inclusion.

Pendergrass, Georgia, US

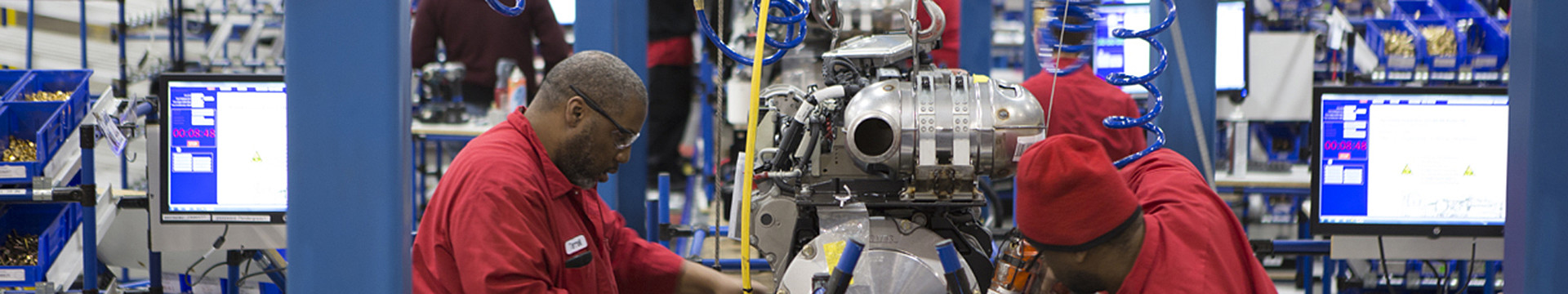

DEUTZ is one of the world’s leading manufacturers of innovative drive systems. Its core competences are the development, production, distribution and servicing of diesel, gas and electric drivetrains for professional applications that is used in construction equipment, agricultural machinery, material handling equipment, stationary equipment, commercial vehicles, rail vehicles and other applications.

Job Summary

JOB DESCRIPTION

|

Job Title: |

Maintenance Technician |

|

Department: Work Location: Remote Eligible: Reports To: |

Maintenance Pendergrass, GA TBD Maintenance Supervisor |

|

Job Code: FLSA Status Shift/Schedule |

60000312 Non - Exempt Full-Time |

POSITION SUMMARY:

The Maintenance Technician supports the operational efficiency of the production department by responding to breakdown calls, trouble shooting, analyzing, and repairing mechanical, electrical, & Pneumatic equipment. The Maintenance Technician must be able to work in a professional manner and provide a clean, orderly, and safe environment while performing work related duties as required by OSHA Standards. The ideal candidate will thrive in a teamwork environment, collaborating with coworkers to achieve common goals.

ESSENTIAL DUTIES & RESPONSIBILITIES:

The Maintenance Technician will be responsible for, but not limited to, the following duties:

- Respond to calls, bring machines to their accurate running state, including troubleshooting, diagnosing, and fixing problems.

- Receive work from supervisor or team lead and carry out assigned duties timely and accurately.

- Complete assigned Preventative Maintenance work on assigned machines.

- Assist with Preventative Maintenance optimization efforts to reduce downtime.

- Dismantle, repair, and re-assemble gear boxes, fans, conveyors, blowers, compressors, pumps, valves, drives, and all allied mechanical equipment.

- Work together with production to increase operator equipment competency.

- Ability to work independently and as a part of a team.

- Collaborate and support cross-functional teams including engineering, facilities, and other departments as needed on time sensitive projects.

- Be willing to participate in any company mandated or recommended training to grow skills within given scope of the role.

- Read and understand blueprints for working systems.

- Promote safety in the work area by understanding and following safety procedures and reporting all accidents in a timely manner.

- Maintain company documentations as needed.

- Utilize CMMS (Computerized Maintenance Management System) to efficiently & effectively complete Preventative Maintenance, repair, and improvement work.

- Must have reliable transportation and a valid driver’s license.

- Drive company vehicle and visit Norcross as required.

- Willingness to work varied shifts, including nights, weekends, holidays, and overtime as needed.

- Perform other duties as assigned.

Supervisory Responsibilities: Individual Contributor

Travel Demands: Anticipated domestic and international travel is approximately 0-10% depending on business needs.

QUALIFICATIONS:

To perform this job successfully, an individual must be able to perform each essential duty satisfactorily. The requirements listed below represent the knowledge, skill, and ability required. Reasonable accommodations may be made to enable individuals with disabilities to perform essential functions.

EDUCATION/EXPERIENCE:

|

Required |

Preferred |

Description |

|

x |

|

HS Diploma or equivalent required. |

|

x |

|

Proficient with basic computer skills and Microsoft Office Suite applications. |

|

x |

|

3 years of experience in Industrial Maintenance. |

|

|

x |

Experience with PLC Motor controls – Pneumatics/Hydraulics/Basic Electrical. |

|

x |

|

Ability to read Blueprints/Electrical prints. |

|

|

x |

Experience with 480V 3 phase power |

|

x |

|

Electro-mechanical skills along with experience in repairing and maintaining production or utility equipment. |

|

x |

|

Must own a basic set of mechanic hand tools |

|

|

x |

Experience with fabrication equipment - Welding ARC-TIG-MIG. |

|

|

x |

Working knowledge of 5S & Lean manufacturing principles |

|

|

x |

Working knowledge of machining equipment - lathe & milling machines. |

- Strong communication skills with the ability to communicate effectively.

- Strong problem solving and decision-making skills.

- Ability to prioritize tasks and manage workload using own initiative.

- Ability to multi-task & work under pressure with limited resources.

- Ability to be a motivated and self-directed without close supervision within a team-oriented environment.

LANGUAGE ABILITY:

Read and interpret documents such as safety rules, operating and maintenance instructions, and procedure manuals. Write routine reports and correspondence. Speak effectively before groups of customers or employees.

MATHEMATICAL ABILITY:

Add, subtract, multiply and divide in all units of measure, using whole numbers, common fractions and decimals. Compute rate, ratio and percent, and draw and interpret bar graphs.

REASONING ABILITY:

Solve practical problems and deal with a variety of concrete variables in situations where only limited standardization exists. Interpret a variety of instructions furnished in written, oral, diagram, or schedule form.

WORK ENVIRONMENT:

The work environment characteristics described here represent those an employee encounter while performing the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform essential functions.

- Manufacturing assembly and warehouse environment. Subject to noise, dust, diesel fuel, oil, and extreme hot/cold temperatures. No A/C.

- If Intern is located in the office area, the noise level in the work environment is usually quiet to moderate.

PHYSICAL DEMANDS:

An employee must meet the physical demands described here to perform the essential functions of this job successfully. Reasonable accommodations may be made to enable individuals with disabilities to perform essential functions.

- Ability to lift, push, or pull up to 50 lbs.

|

Physical Demand Requirement |

Frequency |

|

Concentration |

Daily |

|

Sitting |

Daily |

|

Communication |

Daily |

|

Vision |

Daily |

|

Verbal |

Daily |

|

Standing |

Daily |

|

Hearing/Listening |

Daily |

|

Lifting |

Daily |

|

Bending |

Daily |

|

|

The above job description is not intended to be an all-inclusive list of duties and standards of the position. Incumbents will follow any other instructions, and perform any related duties, as assigned by their supervisor.