EEO Statement

DEUTZ is an equal opportunity employer and considers all applicants for employment based on merit, competence, performance, and business needs. We do not discriminate on the bases of any status protected under federal, state, or local law. Applicants will be considered regardless of their race, color, sex, gender identity or expression, age, religion, creed, national origin, citizenship status, sexual orientation, genetic information, physical or mental disability, military status or any other characteristic protected under federal, state, or local law. In addition to complying with all applicable laws, DEUTZ also has a strong corporate commitment to inclusion.

Pendergrass, GA, US, 30567

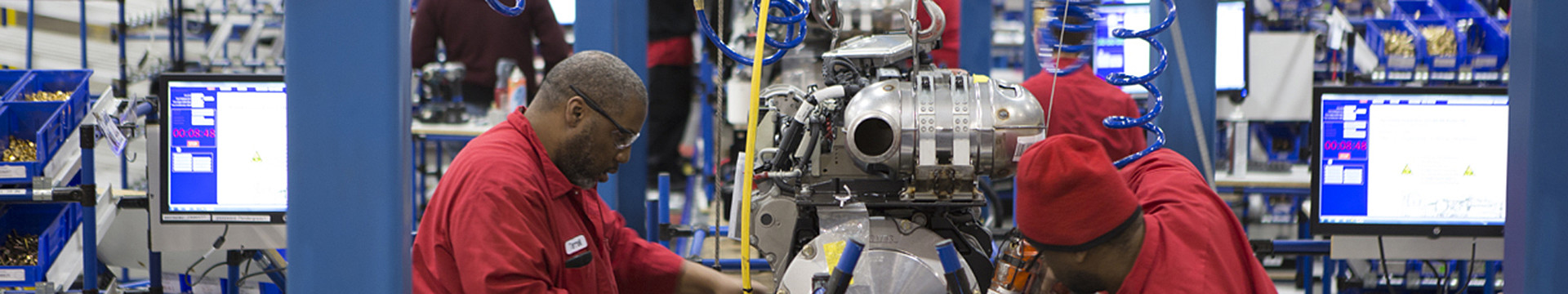

DEUTZ is one of the world’s leading manufacturers of innovative drive systems. Its core competences are the development, production, distribution and servicing of diesel, gas and electric drivetrains for professional applications that is used in construction equipment, agricultural machinery, material handling equipment, stationary equipment, commercial vehicles, rail vehicles and other applications.

Job Summary

As a Continuous Improvement Engineer, you will be the key leader in implementing and overseeing Lean Manufacturing practices to optimize operational efficiency and ensure product quality. Your strategic focus and analytical skills will be critical in identifying improvement opportunities and executing projects that drive productivity and profitability.

ESSENTIAL DUTIES & RESPONSIBILITIES:

The Continuous Improvement Engineer will be responsible for, but not limited to, the following duties:

- Implementation of Lean Principles: lead the application of Lean Manufacturing principles in the plant, identifying areas of opportunity and developing action plans to eliminate waste and improve efficiency.

- Process Analysis and Improvement: Continually evaluate engine assembly processes, using tools such as value stream mapping and root cause analysis, to identify areas for improvement and optimization.

- Staff Capability Development: Collaborate with production teams to implement changes and provide training in Lean methodologies, ensuring effective adoption of new practices. Workshop Leadership.

- Continuous Improvement Project Management: Lead continuous improvement projects from conception to implementation, working closely with various processes to ensure successful execution and sustainability of improvements.

- Establishing Performance Indicators: Define and monitor key KPIs to evaluate process performance, ensuring alignment with the plant's strategic objectives.

- Foster a Culture of Continuous Improvement: Actively promote an organizational culture that values continuous improvement, innovation and collaborative problem solving.

Supervisory Responsibilities: Individual Contributor

Travel Demands: Anticipated domestic and international travel is approximately 10% depending on business needs.

QUALIFICATIONS:

To perform this job successfully, an individual must be able to perform each essential duty satisfactorily. The requirements listed below represent the knowledge, skill, and ability required. Reasonable accommodations may be made to enable individuals with disabilities to perform essential functions.

EDUCATION/EXPERIENCE:

|

Preferred |

Description |

||

|

X |

|

Bachelor's degree in Industrial Engineering, Manufacturing Engineering or related field |

|

|

X |

|

Demonstrated experience in the successful implementation of Lean Manufacturing methodologies in assembly environments. |

|

|

X |

|

In-depth knowledge of Lean tools, such as 5S, Kaizen, Kanban, and value stream mapping. |

|

|

X |

|

Experience managing continuous improvement projects |

|

|

|

|

|

|

Read, analyze and interpret complex documents. Respond effectively to sensitive inquiries. Write speeches and articles using innovative techniques. Make persuasive presentations on complex topics to management, public groups and/or boards of directors.

MATHEMATICAL ABILITY:

Apply advanced concepts such as exponents, logarithms, quadratic equations and permutations. Apply operations to such tasks as frequency distribution, test reliability/validity, variance analysis, correlation technique, sampling theory and factor analysis.

REASONING ABILITY:

Define problems, collect data, establish facts and draw valid conclusions. Interpret an extensive variety of technical instructions in mathematical or diagram form and deal with several abstract and concrete variables.

WORK ENVIRONMENT:

The work environment characteristics described here represent those an employee encounter while performing the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform essential functions.

- While performing the duties of this job, the employee will work within a manufacturing environment with office spaces.

PHYSICAL DEMANDS:

An employee must meet the physical demands described here to perform the essential functions of this job successfully. Reasonable accommodations may be made to enable individuals with disabilities to perform essential functions.

|

Physical Demand Requirement |

Frequency |

|

Concentration |

Daily |

|

Sitting |

Daily |

|

Communication |

Daily |

|

Vision |

Daily |

|

Verbal |

Daily |

|

Standing |

Daily |

|

Hearing/Listening |

Daily |

|

Lifting |

Daily |

|

Bending |

Daily |

|

|

The above job description is not intended to be an all-inclusive list of duties and standards of the position. Incumbents will follow any other instructions, and perform any related duties, as assigned by their supervisor.

Nearest Major Market: Atlanta